Durability

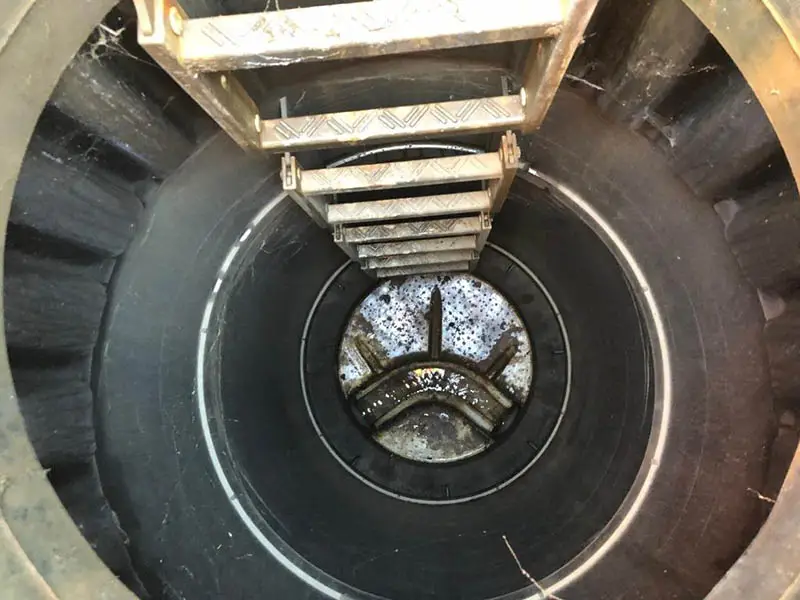

ROMOLD manhole chambers provide an inherent benefit in many aspects of their function and performance, however none more so than their durable life.

Made from polypropylene or polyethene plastics, ROMOLD manhole chambers have a fundamental head start when it comes to durability.

- Polyolefin plastics provide excellent chemical resistance, making ROMOLD chambers a strong solution for corrosive environments that could otherwise damage concrete structures—such as coastal groundwater, acidic soils, and areas affected by hydrogen sulphide from sewage or geothermal sources.

- The erosion resistance provided by a plastic channel ensures that the manhole will perform in a similar manner to that of a plastic pipe, making the risk of scouring a thing of the past. This low surface friction also provides benefits to a gravity system, by keeping the flow moving.

- Polyethylene and polypropylene have excellent ductility, making them resistant to cracking under applied loads. This reduces the risk of leaks or root intrusion, problems typically associated with more brittle materials.

Taking into account the 60 years of experience with gravity sewer pipes produced by polyolefins, the scientific research done by the European plastic pipe industry, the fact that ROMOLD is using virgin polypropylene only, the mandatory durability tests according to EN 13598-2 and the internal tests with extended time periods, ROMOLD is confident of a 100-year service lifetime for their products.

This means that the ROMOLD products that you choose to specify or install will deliver a long and dependable service.

Contact us today to have a chat.