Retention

Manholes are essentially sealed chambers, which means that they will displace water when the groundwater rises. This water displacement creates a floatation force on the chamber, which must be counteracted to secure a stable solution.

For a traditional concrete chamber, the system achieves this mostly through self-weight, with the additional benefit of a flanged base interacting with the fill surrounding the chamber.

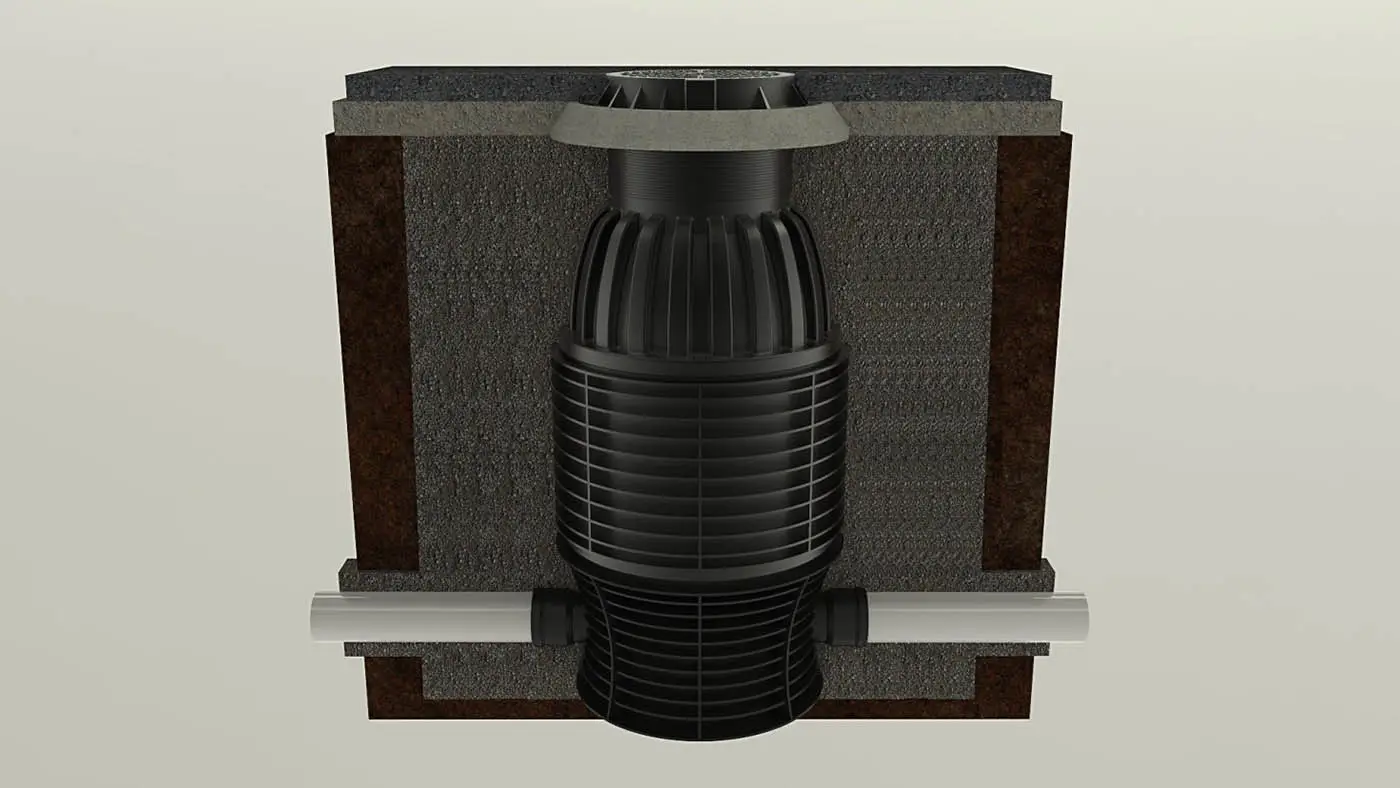

Low-weight is a key feature of a ROMOLD manhole chamber, a great benefit during handling and installation, however it does not add much in terms of ballast to oppose lifting forces.

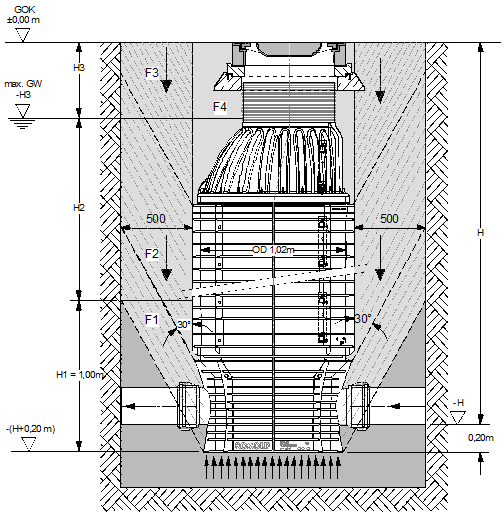

Instead, ROMOLD chambers essentially have moulded in flanges all the way up the height of the chamber, which lock in to the backfill surrounding the chamber. This means that the backfill becomes an integral part of the assembly providing security to the system.

The specification for backfill surrounding a ROMOLD chamber is for granular fill (an AP20 material with a grading envelope which is heavy on fines (see TNZ M/4 spec) is considered to be ideal), applied to a width of 500mm from the chamber wall, and compacted (to a minimum degree of compaction of MDD = 95 % according to AS1289) for the entire depth of the manhole.

The compaction of the granular fill ensures good density of the backfill, providing ballast to the manhole system. The second but equally important purpose of the compacted backfill is to support the cover and load distribution ring, allowing the manhole to be fully trafficable.

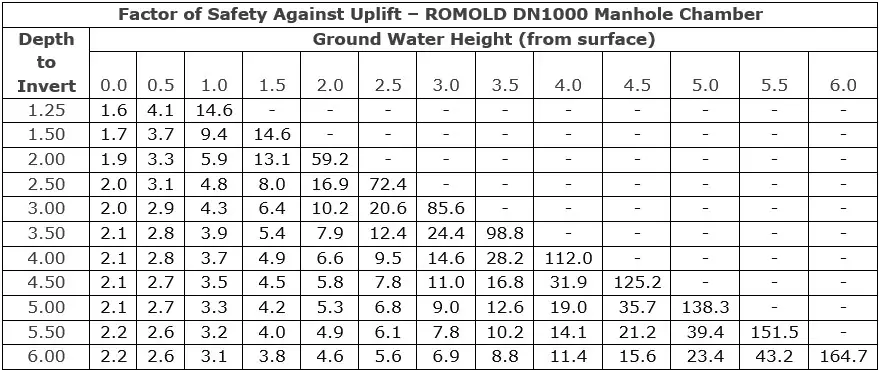

Calculations have been used to determine the retention safety factor for various depths, and various groundwater levels, under this arrangement. This shows that the minimum safety factor for retention is 1.6, which exceeds the 1.25 requirement stated in NZS 4404.

Retention table

AML have confirmed this design by testing the retention of a ROMOLD manhole chamber. This test used a flat plate mounted under a DN1000 manhole chamber, to exert an upwards load applied by a digger. A digital loadcell was employed to accurately determine the applied force. For the 2m deep manhole, the applied load reached 7.5 ton at peak, without any movement from the chamber. The displacement of the manhole is approximately 1.55m3, so 1.6 ton of uplift forces in saturated ground conditions. This proved that the retention provided by the standard installation is well in excess of groundwater lifting forces and that a very good safety factor is maintained.

For installations where the compaction of granular fill may not be reliable, we recommend to use Flowable Fill as an alternative. This is a low MPA concrete that can be re-entered in the future if required. When applying Flowable Fill a support load will need to be applied to the chamber to prevent shifting under the buoyancy effects of the fill. Often the best solution here is to rest the digger bucket on the top of the chamber until the fill has set. Good bunding is also recommended to reduce fill costs.

Contact us today to have a chat.